In this post, student blogger Michaela Bosman (2nd year Literature) investigates the concept of a ‘circular economy’ and some close-to-home examples of how it can be key to transforming the food system.

English consumers often tout recycling as the most valuable measure we can take to reduce our waste and contribute to a mode of living that’s sustainable for the planet. But many of us are sceptical about what actually happens to the recycling waste once it disappears into the lorry – and rightly so. Often the materials used to make the products (including packaging) which we dump in our recycling bins are blended together in such a way that makes separating them near impossible. This means they won’t be recycled, and will instead be sent to a hole in the ground where they’ll stay intact for thousands of years, unable to biodegrade into soily richness.

Rethink recycling?

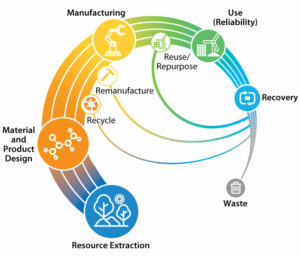

The ways in which materials are combined in products, which can limit or extend the life of those materials, are a key focus of the Ellen McArthur Foundation’s work on a circular economy. One of the Foundation’s concerns is how we – consumers and manufacturers – might use and reuse materials to reduce the waste that sits in landfill. In a circular economy, the design of each product takes measures to extend the life of its comprising materials, or to extend the life of the product itself. Recycling the constituent parts of the product is a single facet of a circular economy and can only be done if the design engenders an energy-efficient separation of the materials. If we are going to recycle something in a circular economy, manufacturers must think about what the products will be recycled into: if they use toxic ink on a piece of paper, it can’t then be recycled into a cereal box. When thinking about the lifecycle of a product or material, the Foundation uses a concept called cascading, which asks how we can keep an item in use for as long as possible. Cotton in a T-shirt – when the T-shirt has lost its use as clothing – can be cascaded back into the economy in the form of wadding, stuffing, or sound insulation – if it is designed with repurposing in mind.

A close-to-home example of a product-design concern in a circular economy is the inside of the single-use cups in the YSJU canteen: they’re coated with a thin plastic film (so that the liquid doesn’t seep out of the porous cardboard) which takes an incredible amount of energy to detach from the recyclable part of the product. This, in many cases, renders the whole product unrecyclable. But YSJU is taking steps towards a more circular economy on the single-use cup front. The new 20p charge reduces our willingness to use the disposable cups, and the introduction of the ceramic ones encourages us to opt for the cups that’ll be washed and reused. This means, of course, that you need to have your cuppa in the canteen. If you need to take it away, though, YSJU has sourced a great product with sustainability in mind. The plastic that the reusable takeaway cups are made from can be recycled an infinite number of times: in theory, the product never needs to go to landfill. If your cup gets cracked, you can just return it to the company to be recycled into a new one. The company, Ecups, is based on the outskirts of York, which means the product distribution emits a lower carbon footprint than if the procurement team had sourced the cups from further away. Buying many of YSJU’s products locally is yet another measure the university takes to promote its wider objective of sustainability.

Ecups are made with a circular economy in mind

Sustainability and regeneration lie at the core of the circular-economy model. So, to create more sustainable university food systems, YSJU is revamping its catering practices with the aim of achieving bronze, and later silver, certification by Food for Life. You can look at all the criteria for silver certification here, but one particular metric is sourcing local produce, including meat that can be traced back to the farm. This criterion can ensure low carbon emissions in more ways than one: local distribution means low fuel usage, and by locating the farms themselves, we can choose – within our budget – the ones which use the most sustainable production methods. I picked out this metric to discuss because local food distribution is an oven-ready way to demonstrate YSJU’s commitment to sustainability. But there’s more going on with Food for Life, so keep your eyes peeled for my next post in which I focus solely on this.

YSJU food waste (such as leftovers from the Living Lab Burns Night potluck celebration, pictured here) undergoes anaerobic digestion which generates power for the national grid

Another way YSJU plans to contribute to a circular economy is in graduation gowns. From November this year, the gowns we’ll hire for graduation will be made from recycled plastic bottles. Talk about repurposing a material. But I do wonder where EVS (the company that makes these gowns) source their plastic bottles: I wonder if they can only use certain ones, something manufacturers might consider if they want to move towards a circular economy. Of course, I don’t mean plastic bottle manufacturers should all think about graduation gowns; I mean they should think about the plastic’s next use, and whether it can have another use at all. But the circular-economy model doesn’t work if the consumer doesn’t buy into it and do their part to recover the materials. Luckily for YSJU students, these graduation gowns are roughly half the price than the previous, less circular ones (circular in economic theory, not in shape). The price makes buying into EVS’s business model easy.

Companies committed to sustainability are rising in popularity and accessibility – let’s find more to support

In this post I wanted to stay within the bounds of food systems – this semester’s Living Lab topic – when discussing how YSJU contributes to a circular economy (we find plastic bottles in the kitchen, right?). But there are other ways too, for instance using carpet tiles from Interface; you can find out more about them here. As you can see, circular-economy thinking has rooted itself in YSJU procurement, but there is always room to create more sustainable ways of functioning. I suppose I’m preaching to the converted, because you’re reading the Living Lab blog, but a lot of the onus to demand change at the university is on the student body. YSJU reacts to the most vocal of us. So, let’s speak out, for a healthier planet.

For a closer look at some of the principles of a circular economy, you can listen to Ellen McArthur talk about it in the video you can find on this page of the Ellen McArthur Foundation website.